Battery

Press releases

-

Over 90 per cent capacity: ID.3 battery impresses in ADAC’s 160,000-kilometre endurance test

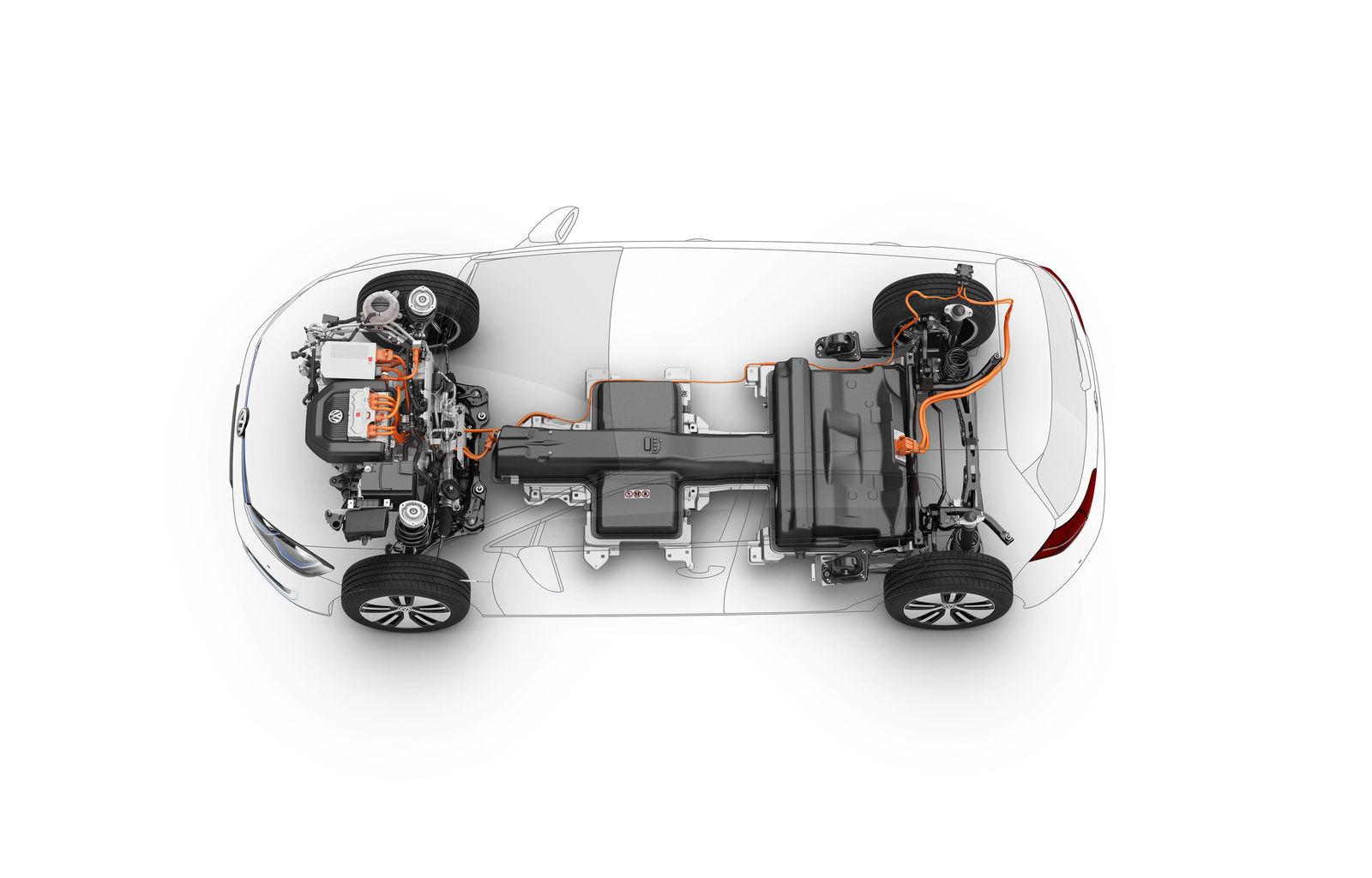

The ADAC testers have given the ID.3 an excellent report after four years of endurance testing. The engineers at the Test and Technology Centre in Landsberg am Lech (Germany) covered more than 160,000 kilometres. The key takeaway: the high-voltage battery still has a net capacity of 91 per cent. An ID.3 Pro S with a net battery energy content of 77 kWh was tested. As for all other ID. models, Volkswagen guarantees that the battery of the ID.3 still has at least 70 per cent of its original net capacity after eight years of operation or 160,000 kilometres of driving. -

ID.7 Pro S covers 941 km on one battery charge during efficiency test

Volkswagen has reached a new efficiency milestone on a circuit in Nardò, southern Italy: an ID.7 Pro S with a standard technology package and 210 kW (286 PS) covered a distance of 941 kilometres on just one battery charge (86 kWh net). This significantly exceeded the model’s maximum WLTP range (combined) of up to 709 kilometres by 232 kilometres or 32.7 percent. During the 941-kilometre tour, the ID.7 Pro S had an average consumption of just 9.2 kWh/100 km – an exceptionally low figure. Converted to a diesel equivalent, the average consumption achieved in Nardò corresponds to about just 1 litre per 100 km. The aim of the test in Nardò was to determine the maximum efficiency of the ID.7 Pro S introduced in 2024. -

All-electric ID.7 Pro S covers 794 km on one battery charge

Driving the new all-electric ID.7 Pro S, the Volkswagen Team Switzerland headed by project lead Felix Egolf, an expert in long-distance driving with electric cars, successfully covered a total of 794 kilometres with a single battery charge in a net driving time of 15 hours and 42 minutes. This significantly exceeded the model’s maximum WLTP range (combined) of up to 709 kilometres. The comfortable touring saloon was driven on public roads and in normal traffic flow throughout the entire daytime journey.

Basic Infos

-

The new ID.3

International Media Drive