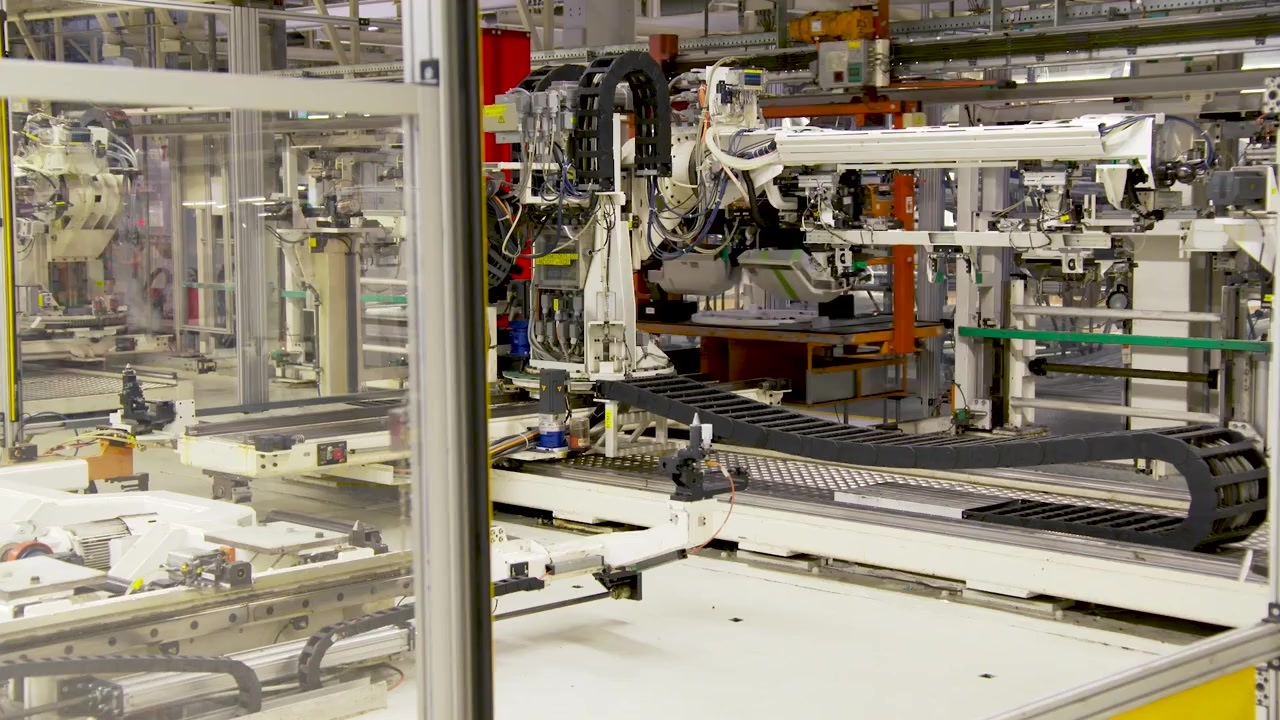

The Wolfsburg plant is the Volkswagen Group’s main plant and one of the world’s biggest automobile manufacturing facilities. It currently produces the following Volkswagen models: Golf, Golf Variant, Tiguan and Touran. It also makes components such as injection-molded parts or drive shafts. Immediately adjacent to the Volkswagen is the Autostadt. This experience and competence center provides information about the development of automobility as well as the history and value of the Group brands. More than 46 million people people have visited the Autostadt since it opened in 2000.

Wolfsburg

Press releases

-

New SUV from Wolfsburg: the Volkswagen Tayron is now rolling off the production line at Volkswagen’s main plant

The newest member of the Volkswagen portfolio – the Tayron – was given a grand reception this week when employees from nearly all the different disciplines joined Wolfsburg Plant Manager Uwe Schwartz and Works Council member Jürgen Mahnkopf for the symbolic start of series production. -

50 years of Golf production: Volkswagen plant in Wolfsburg celebrates its bestseller

Wolfsburg and the Golf – a perfect combination for 50 years. Mass production of the first model generation began at Volkswagen’s main plant in spring 1974. This Monday, the company celebrated the anniversary with a ceremony under the motto “50 years of Golf production”. The guests gathered in Hall 12 of the Wolfsburg plant included employees from Golf production along with the brand Board of Management led by CEO Thomas Schäfer, representatives from the Group Board of Management, the Chair of the General and Group Works Council Daniela Cavallo and other leading Works Council members, as well as numerous representatives from the world of politics. Minister President Stephan Weil paid tribute to the outstanding achievements of the Volkswagen workforce and the economic significance of the Golf for the State of Lower Saxony and Germany as an industrial powerhouse. -

Green light for series production: new Golf starts rolling off assembly line at Wolfsburg plant today

Series production of the new Golf has started at the Volkswagen plant in Wolfsburg: the first car from the technically and visually revamped eighth model generation to roll off the assembly line in Hall 12 today was a Golf Style in anemone blue metallic – almost exactly 50 years since the very first series Golf was built in Wolfsburg.