With the start of production of the ID.3 in January 2021, the Transparent Factory in Dresden has evolved into the "Home of ID." - and brings the "Love Brand" Volkswagen to life with a first-class visitor experience. During the tour, which is offered in various languages, visitors learn how the ID.3 is manufactured and what the future of mobility looks like at Volkswagen. Furthermore, customers and guests can even get up close to the ID.3 in production by accompanying the vehicle along the production line for a short time and trying their hand at it themselves - an exclusive and unique experience in the automotive world. In addition to advice on models and technology from a specially trained team of experts, various test drives in electric vehicles such as the ID.3, ID.4, ID.5, ID.7 and ID. Buzz through Dresden will take place every day. After the Autostadt in Wolfsburg, the Transparent Factory is Volkswagen's second largest national delivery centre. In addition, the Transparent Factory, located not far from the city centre, is a top attraction and sought-after event location in the Saxon capital, hosting up to 150,000 guests and more than 200 events every year.

Dresden

Press releases

-

ID.3 GTX FIRE+ICE: Volkswagen starts series production in Zwickau and Dresden

Today the series production of the ID.3 GTX FIRE+ICE has started in Saxony. The 1,990 vehicles roll off the production line at the Zwickau vehicle plant and the Transparent Factory in Dresden. The model was developed in collaboration with the performance sportswear brand BOGNER FIRE+ICE, part of the Munich-based luxury sports fashion company BOGNER, just like the legendary Golf II Fire and Ice, which became a surprise success in the 90s and now enjoys cult status among fans. In tribute to the original model’s debut year, only 1990 units of the ID.3 GTX FIRE+ICE will be available to order. Prices in Germany start from €56,020. -

Premiere at the ID. Meet: apprentices from Volkswagen Sachsen present ID.5 GTX „Xcite“ show car

Volkswagen presents today the ID.5 GTX „Xcite“ to the public for the first time today at the ID. Meet in Locarno (Switzerland). This vehicle is an individual product made by apprentices at Volkswagen’s three locations in Saxony, at Zwickau, Dresden and Chemnitz. For one year, 14 of the best budding specialists worked on a project to demonstrate their skills with considerable creativity and responsibility under expert supervision – from the first design through the adaptation of the bodywork and paintwork to technical commissioning. In addition to sustainability, reflected by vegan leather in the interior, the main focus of this year’s project was on holistic mobility. The ID.5 GTX „Xcite“ already has on board an electric skateboard for the last few meters to the driver’s destination. This is the eighth project of its type completed since 2014. -

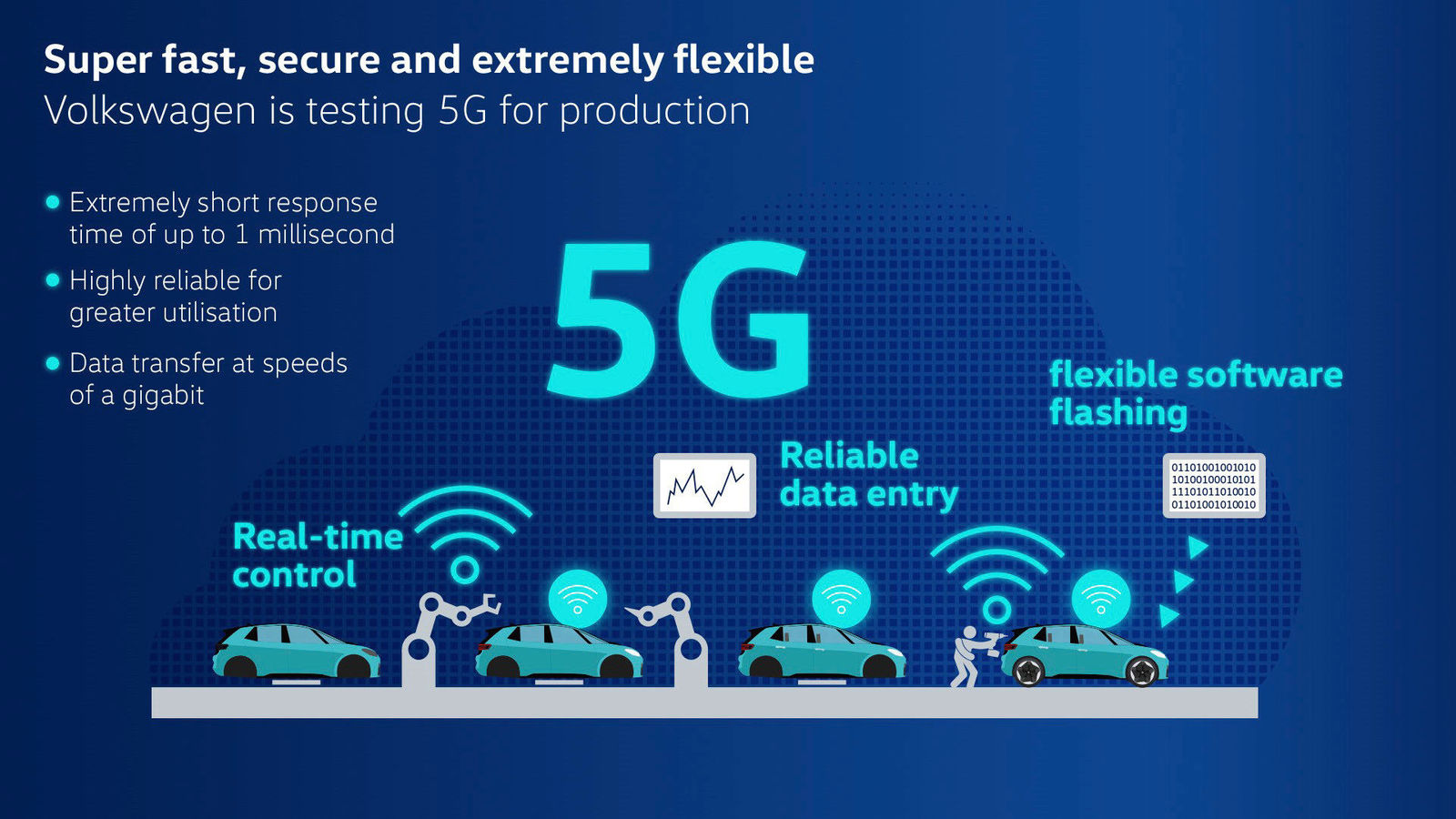

Volkswagen tests 5G for production on its way to smart factories

Volkswagen is taking a further step in the direction of fully networked factories. A local 5G standalone network (“campus network”) is now available at its main plant in Wolfsburg that initially covers the main production development center and the pilot hall. The pilot project will test whether the 5G technology meets the demanding requirements of vehicle production with a view to developing this for industrial series production in the future. A dedicated 5G radio frequency will be used to safeguard secure, delay-free transmission of data. The Transparent Factory in Dresden has also put a so-called “5G island” into operation. Volkswagen undertakes setup and operation of the 5G infrastructure itself in a move designed to build up competitive expertise in using this important technology of the future and ensure data security.