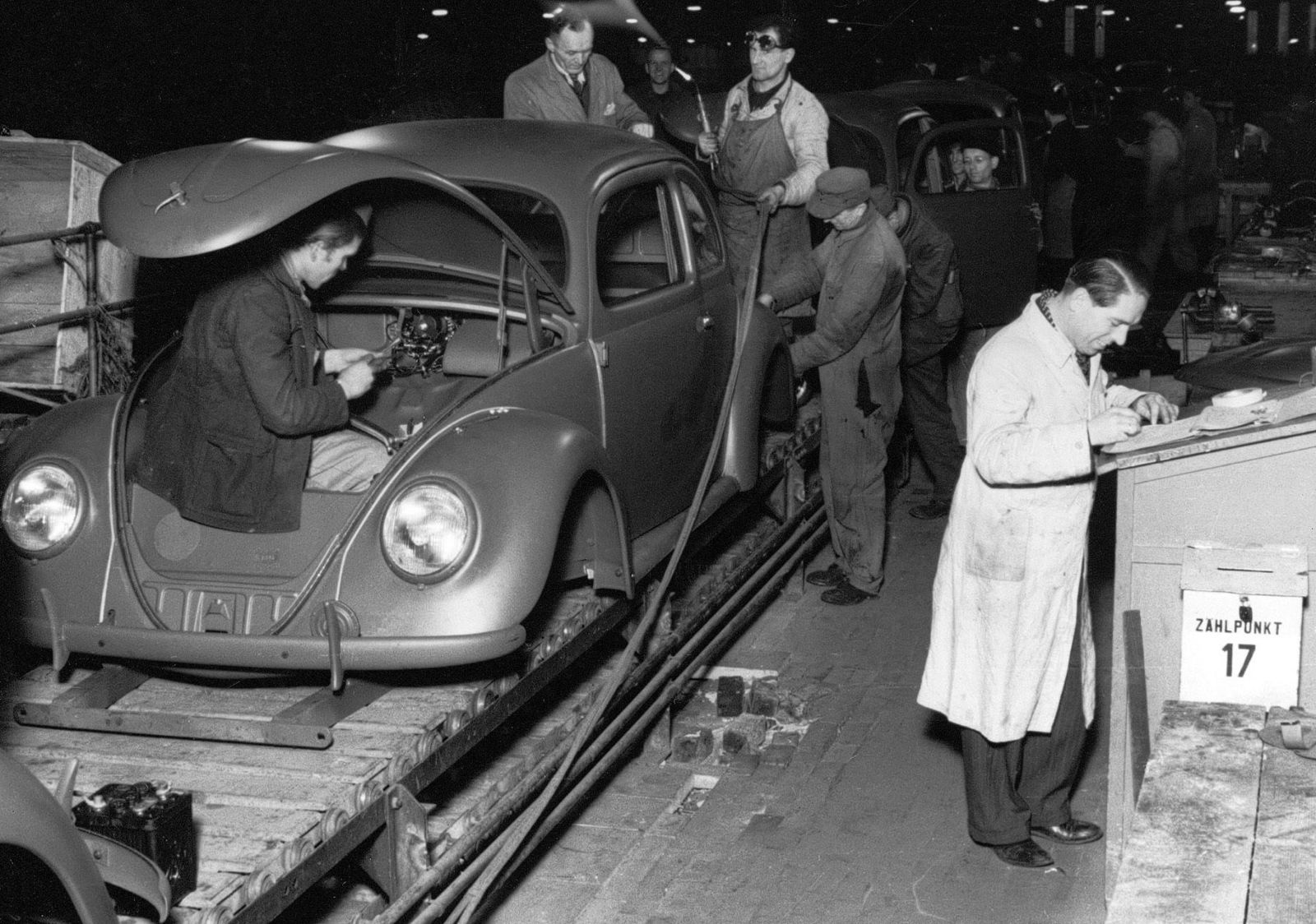

vehicles were visible symbols of hope; a new beginning for the car plant under British control.

By the end of the Second World War in 1945, just 630 of the People's Car known as the 'KdF-Wagen' had been built. The state-of-the-art factory in what was to become the present-day Wolfsburg, built specially to make the vehicle, was integrated into Germany's wartime armaments industry, producing mainly military goods. The site was occupied by US troops on 11th April 1945. In June 1945, the British Military Government took over trusteeship of the factory with its workforce of some 6,000 people. On 22nd August 1945, the recently appointed 29-year-old Senior Resident Officer Major Ivan Hirst acquired an initial order for 20,000 Saloons, thereby providing the factory and its workforce with a future, and avoiding the threat of decommissioning and dismantling. The vehicles were intended mainly for use by the occupying Allies, but also to help provide health-care services in rural areas. Production