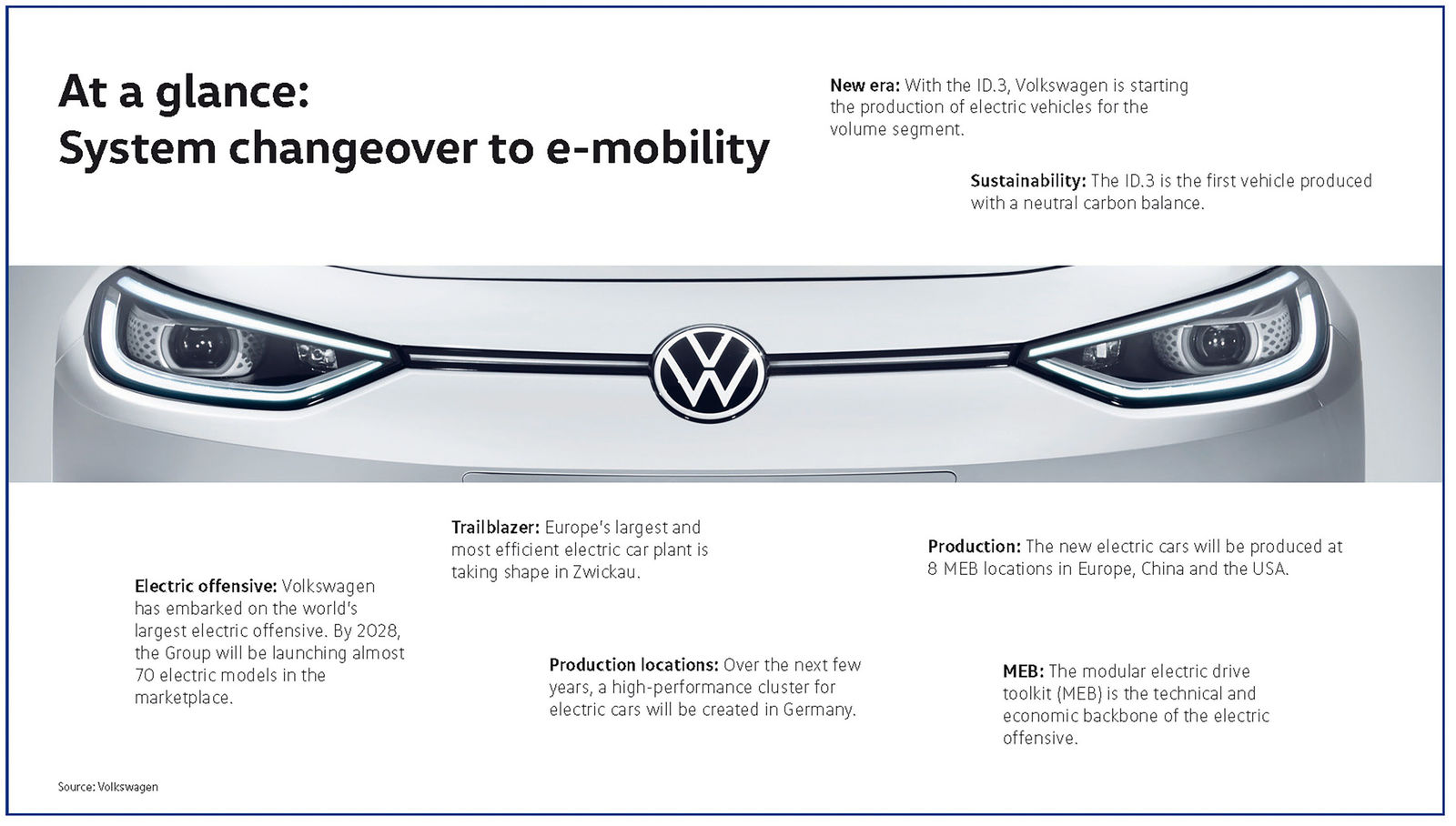

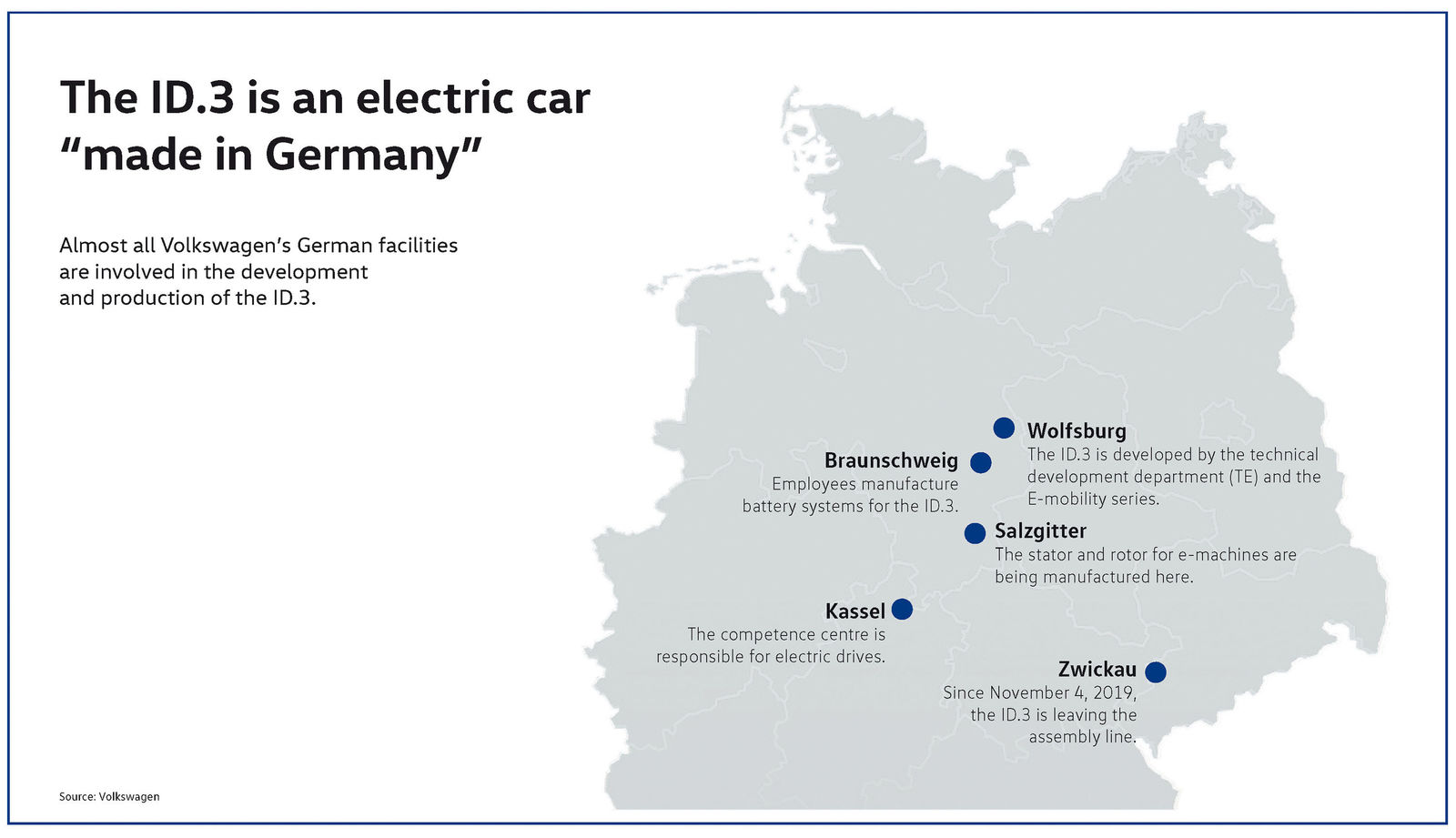

Electric offensive: Volkswagen starts largest e-offensive in the automotive industry with production of the ID.3 and ID.4 e-vehicles in Saxony and is committed to Germany as a production location

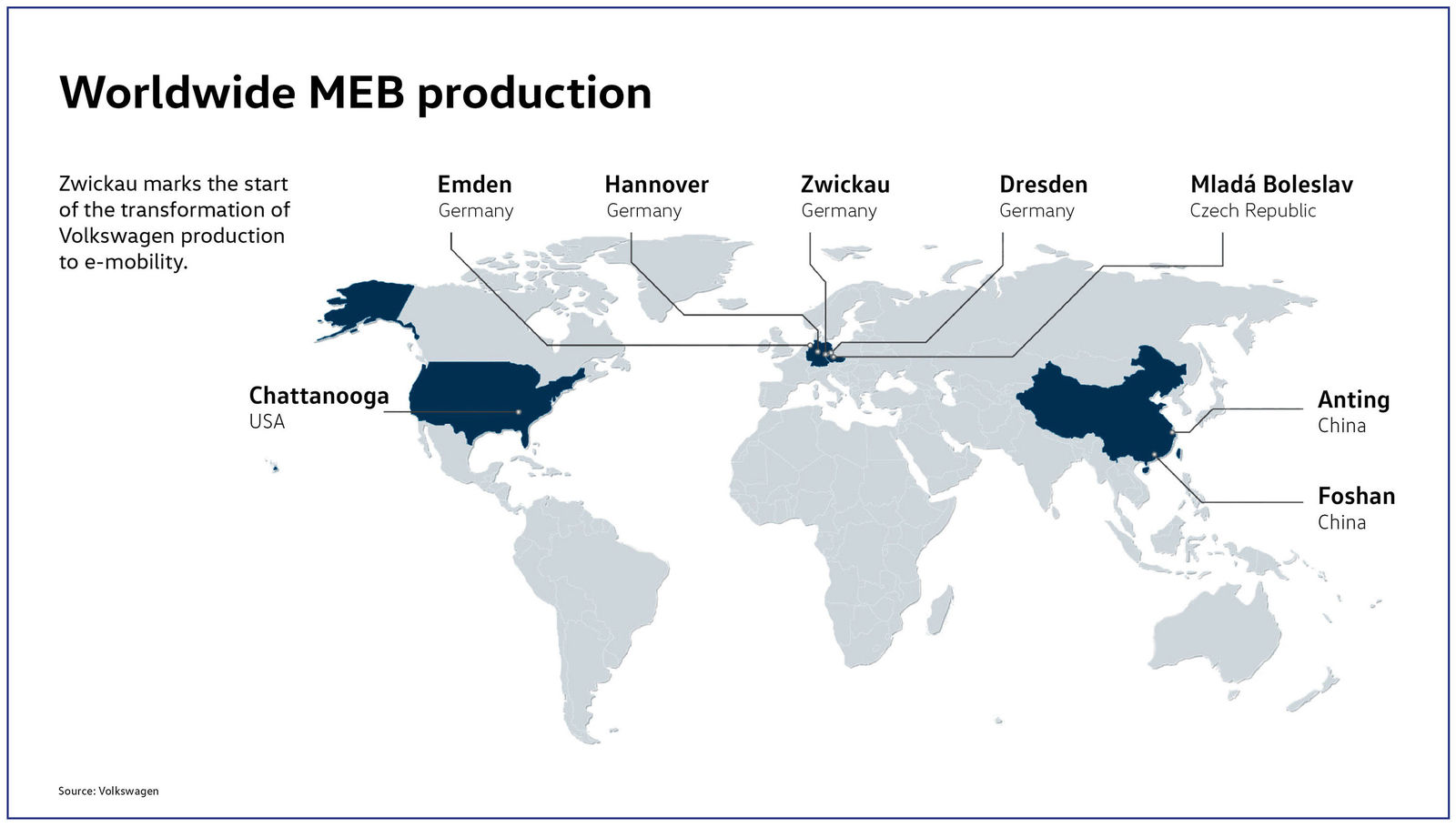

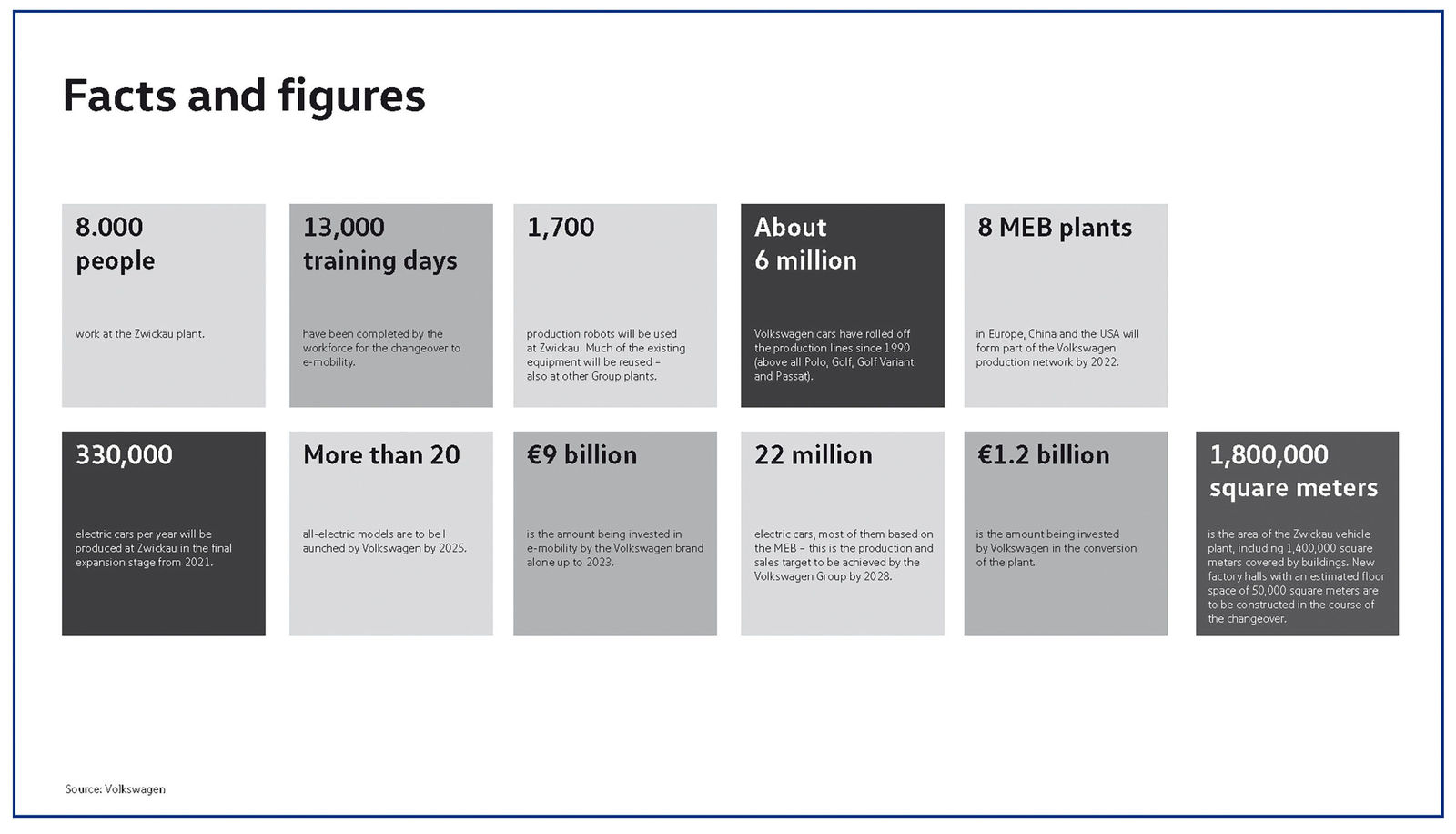

Production sites: Over the next few years, production will be expanded to a total of 8 locations - in addition to other German locations, also in China and the USA

Decarbonization: The Volkswagen group is focusing on sustainable production and carbon neutrality

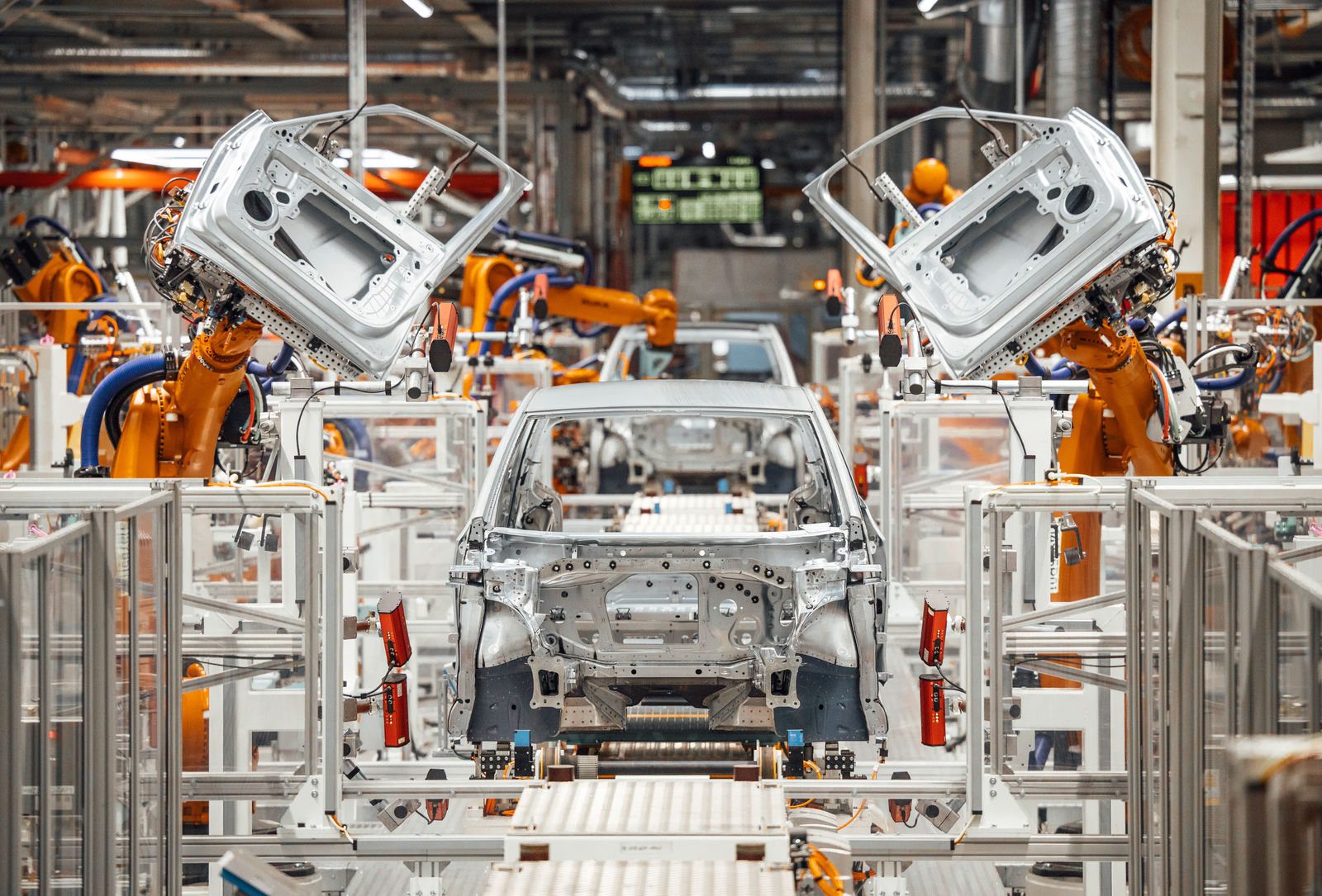

Pioneering role: The Zwickau plant is the largest and most powerful electric car plant in Europe and has been transformed into a high-tech factory with investments of over 1.2 billion euros

System changeover to e-mobility: From 2021, the Zwickau plant will have a production capacity of around 300,000 electric cars - not just from the Volkswagen brand - based on the Modular Electric Drive Kit (MEB)